ALL A QUESTION OF TIMING

Combined with passion, knowledge, patience, care and attention to detail, we produce fruit brandy of the very highest quality without compromises.

It all begins with selecting the fruit, but distilling is by no means the end of the process. Instead, our brandies are left for many years to settle and mature into exquisite distillates which are strong and full-bodied, yet at the same time fruity and delicate.

FRUIT QUALITY

ONLY THE BEST IS GOOD ENOUGH

The art of nature. Fine brandy results only from fine fruit. That is why we apply exacting standards in the choice of our raw material. After all, not every apple or berry is suitable for making outstanding brandy. We use both cultivated varieties such as the Wachau apricot and the rare Gravenstein apple as well wild-growing fruits such as the wild raspberry and the sloe plum. These are sourced from areas where the conditions are ideal for that specific variety to grow and ripen to perfection.

Every apricot, every pear and all other fruit we use stays on the tree or the bush right up until the point when it reaches its maximum sugar concentration. This approach can take several weeks and demands great patience from us and our fruit growers, for not all fruits of a single variety ripen at the same speed. However, healthy, full-bodied fruit is and remains the only basis for an exquisite brandy, so we are happy to watch and wait.

We have known most of our fruit growers for many years and share a common passion for the finest quality. When growing and ripening conditions are poor, we collectively hold our breath. If the crop does not meet our exacting standards, we may decide to make none of a particular variety that year. But in good years there is nothing like the feeling of picking the fruit when it is perfectly ripe and full of flavor. That is the stuff distillers’ dreams are made of.

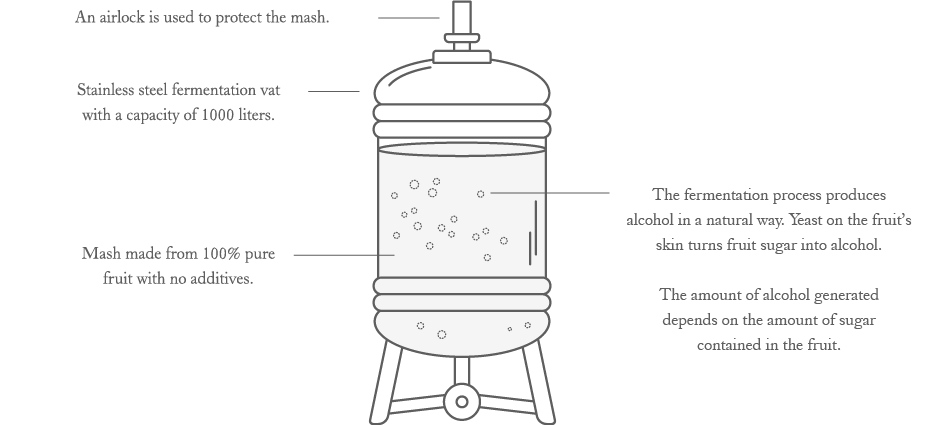

FERMENTATION

NATURAL TRANSFORMATION OF FRUIT SUGAR

ATTENTION TO DETAIL FROM START TO FINISH

The art of transformation. Attention to detail and absolute cleanliness are essential from start to finish. This goes for both the harvesting and the processing of the fruit. Once sorted and cleaned, it is then mashed and placed into special vats.

Within just a few hours natural yeast on the fruit’s skin starts to transform fruit sugar into alcohol in a process known as natural fermentation. This could be accelerated using artificial yeast, but that would be contrary to our principles. Instead, we leave the mash to ferment in a 100% natural way. Only then are we able to fully preserve the pure fruit flavor.

This is why we never add anything to the mash – it would interfere with the natural fermentation process and have a negative impact on the final product.

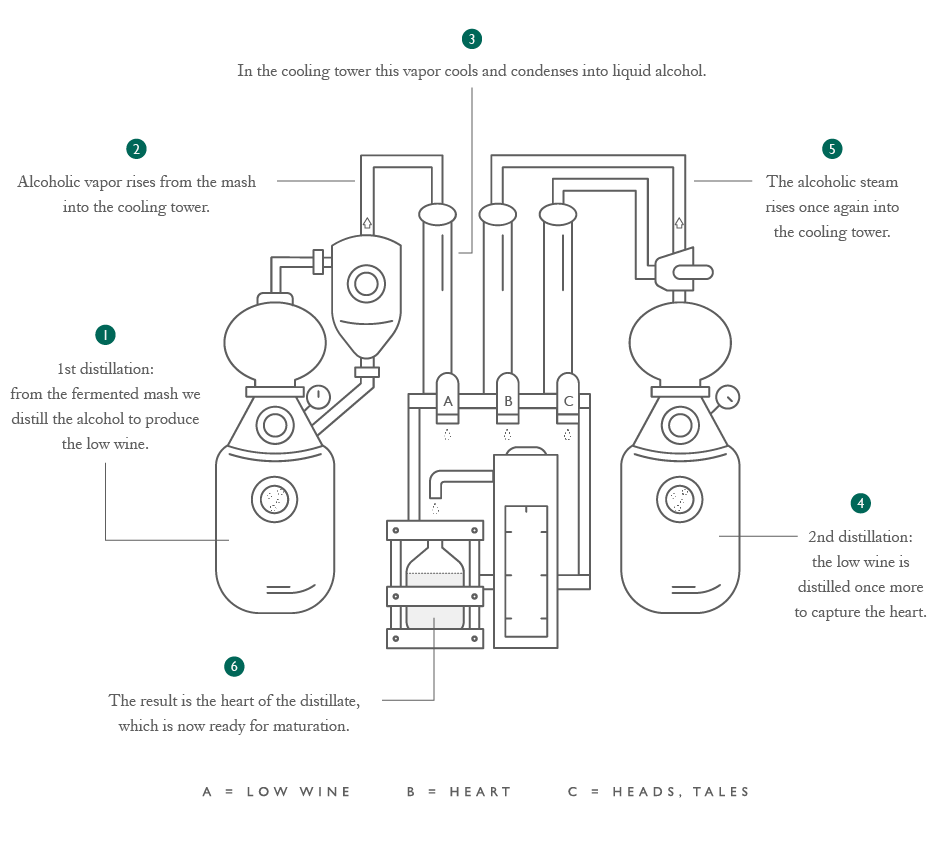

DISTILLATION

AS SLOWLY AND CAREFULLY AS POSSIBLE

DOUBLE DISTILLING PROCESS

The art of concentration. Once fermented, the fruit mash is twice distilled in our copper pot stills following an old Tyrolean tradition.

This process of transforming the fermented mash into fruit brandy takes time and must be carried out as slowly and gently as possible. It is the alcohol which carries the rich flavors that must be preserved during careful distillation.

The first run produces what is known as the low wine. This is then distilled a second time to extract the actual distillate – the so-called ‘heart’ – requiring a combination of intuition, expertise and experience. This ultimate step determines whether the best mash will actually result in outstanding brandy. And, of course, the distiller adds his own personal touch to each variety and vintage. To produce one liter of the precious heart we use up to 80kg (175 pounds) of fruit.

OUR DISTILLING PROCESS

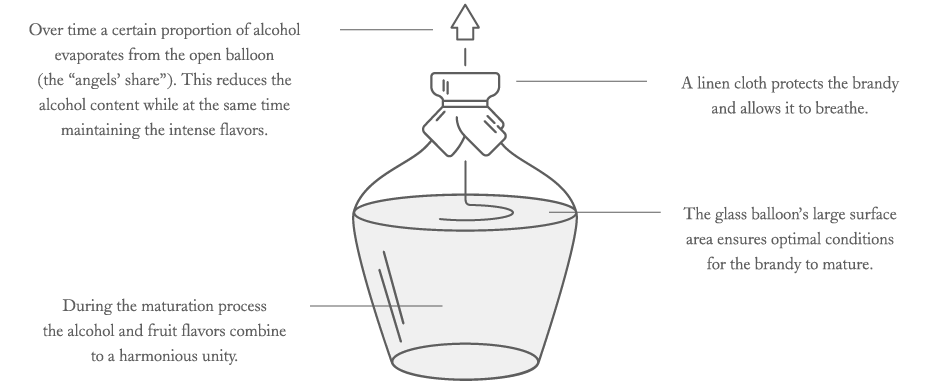

MATURATION

GOOD THINGS COME TO THOSE WHO WAIT

PATIENCE IS THE KEY TO A FINE FRUIT BRANDY

The art of waiting. We give our brandies time. Lots of time. Because we know that patience is the key to a fine fruit brandy. Our distillates are left to mature in glass balloons for up to ten years, giving the flavors the chance to fuse with the alcohol and create a delicious balance. Throughout this process we make regular checks and enjoy following the maturation process of each distillate, year by year.

Over time a certain proportion of the alcohol contained in the distillate evaporates. This is known as the angels’ share. Furthermore, alcohol and fruit flavors combine and balance to a harmonious unity during the long maturation period. These two developments result in a much smoother fruit brandy full of finest fruit flavors: a true Rochelt.

Leaving the brandy to mature for so long also means that we can minimize the amount of additional spring water, resulting in a crystal-clear distillate full of fine fruit flavors that linger on the palate long after drinking. As original Tyrolean tradition demands, Rochelt brandies requires no filtration – a process which would compromise the quality of an distinguished fruit brandy.

OUR BRANDIES ARE LEFT TO MATURE IN GLASS BALLOONS FOR UP TO TEN YEARS.

“The quality of a distillate is partly a result of its careful maturation, the age of a fruit brandy.”

Annia

Rainer-Rochelt

WHAT WE BELIEVE IN

OUR PRINCIPLES

| 1 | We use only flawless fruit from the best growing regions. Our brandies are made using nothing but pure fruit from regions with ideal growing conditions, where it can develop and ripen to perfection. |

| 2 | We cooperate closely with our fruit growers to coordinate how we work. We know not only where our fruit comes from but also the people behind it. The fruit growers we work with share our passion for outstanding quality |

| 3 | We ensure strict cleanliness when processing the fruit. We guarantee that only ripe and clean fruit makes its way into our fermentation vats. If the crop does not meet our exacting standards, we may decide to make none of a particular variety that year. |

| 4 | We leave the fruit mash to ferment naturally. Alcohol is generated by the natural fermentation of sugar contained in the fruit, without the addition of yeast or other additives. Only in that way are we able to fully preserve the pure fruit flavor. |

| 5 | We distill the fermented mash as slowly and gently as possible. We carefully distill the fruit mash twice in our custom-built copper stills. First to low wine, which is later distilled a second time to extract the highly desired actual distillate – the so-called ‘heart’. We use up to 80kg (175 pounds) of fruit to produce one liter of this precious heart. |

| 6 | Our brandy matures slowly over several years to the point of perfection. Following an old Tyrolean tradition, our distinguished fruit brandies are left to mature for up to 15 years to the point of perfection, when alcohol and fruit flavors combine and balance to create a harmonious unity |

| 7 | We closely monitor the distilled spirits throughout the entire production process. Strict quality checks are essential to guarantee the highest level of quality. That is why we regularly analyze, taste and inspect our brandies as they mature and develop. |

| 8 | Rochelt fruit brandy is unfiltered. While our distillates rest, the weight and strength of the alcohol diminishes. Rochelt brandies thus contain minimal water only and require no filtration – a process which irreversibly compromises the quality of a distinguished distillate. |

| 9 | We strive to produce fruit brandy which is strong, yet comforting and smooth. Thanks to its long maturation period our fruit brandy is both smooth and soft, yet strong and full. While bouquet is contained in the glass, the palate benefits from a truly amazing concentration of fine fruit flavors. |

| 10 | Our distillates are 100% natural and burst with the finest fruit. Strong, complex, subtle and unmistakably fruity – Rochelt distillates are immediately recognizable, providing intense drinking pleasure in every single drop. |